Building ICF

Insulating concrete forms (ICFs) are expanded polystyrene panels that are stacked into the shape of the exterior walls of a building. Steel rebar is installed as the panels are stacked. Concrete is then poured inside, creating a foam-concrete sandwich. The result is a house or commercial building that is exceptionally strong, energy efficient, quiet, comfortable, and durable, that can be built in any style.

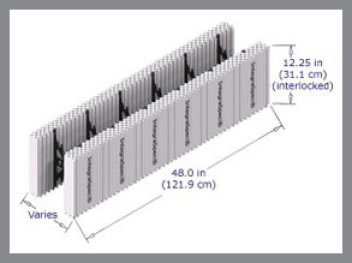

IntegraSpec® is an Insulated Concrete Form (ICF) consisting of 2 panels of expanded polystyrene (EPS) married with high impact polystyrene inserts used to hold patented webs/ spacers designed to secure rebar as needed. Once stacked together, these forms represent a mold ready for concrete placement, similar to a traditionally poured concrete wall; however, ICF forms never leave the concrete.

1. Structural Support: (Concrete & Steel)

2. Super Insulation: (2 1/2” EPS panels on each side with 6”, 8”, or more concrete between them)

3. Studs/Furring: (1 5/8” Studs at 8″ on center)

4. Air/Vapor Barrier: (Low permeate EPS in continuous contact with concrete)

5. Finishing Substrate: (Single material EPS Type II)

_______________

Systems we use include:

• ICF walls

• Spray foam insulation (both open and closed cell) in walls, roofs, and floors

• Unvented roof systems

• Unvented crawlspaces

• Under-slab insulation

• Geothermal heating/cooling

• Ultra high efficiency windows

• Some high performance products we prefer to use include:

• Integraspec ICFs

• Alpen Windows

Does building ICF structures take longer?